Bio-processing Machinery

Bio-Processing Machinery Introduction

Starting from 2015, KLIM started research into Acidulo® biodegrading technology discovered in sugar environmental protection process, while collaborating with foreign research institutes to develop this technology in the filed of biodegradable waste processing. Our company has always been a keen supporter in environmental protection, supporting national environmental policy and power conservation is our ongoing pursuit in product design, manufacture and application. By continuously provide our client with environment-friendly and power-conservative product to satisfy their needs, we have accumulated substantial expertise in design and manufacturing of environmental protection equipment, throughout the fields of sugar making, paper making, metal casting and others. Following China’s green initiative push in every industry, research and application of new environmental protection technology, process and equipment has become our company’s new direction. After understanding the advantages of Acidulo® biodegrading process, considerable experiences are gained from experiment into its effectiveness in processing biodegradable waste. At the same time, domestic design and manufacturing of bio-processing equipment, ranging from 2kg home kitchen waste processing to 10t-300t large dining hall or vegetable processing plant waste processing, are realized.

Bio-Processing Machinery Feature

1.Major feature of this processing system is the prolonged degrading capability, significantly cutting down on additional microbes cost. Under normal usage, there is no additional microbes cost for 3-5 years.

2.Our equipment can reduce organic waste down by 90%, the 10% left is rich in nitrate, potassium, phosphorus and various fertilizing component, making it an ideal fertilizer, after further processing, it can be used as organic fertilizer for gardening.

3.Our method as little nitrate emission, thus limiting environmental problems caused by acid rain, substantially reducing burden on environment compared to other methods.

4.Our equipment creates an environment of acidity at pH 4.0-6.0 and temperature at 100 C. While acidity helps to eliminate bacteria that lives in slightly acidic and alkaline conditions, heat generated during processing can kill bacteria and virus existing under 80 C.

Bio-Processing Machinery Application

1. Microbial tea fermentation project

2. Microbial Chinese traditional medicine waste processing project

3. Microbial fruit and vegetable waste processing project

4. Microbial flower planting base application

5. Unmanned public toilet project

6. Microbial kitchen waste early processing application

7. Microbial fish powder making application

8. Sewage plant sludge treatment

Bio-Processing Machinery Advantages

1. Occupies minimal space with almost no odor, significantly impacts nearby environment.

2. Substantial weigh reduction helps to reduce transportation cost and prevent secondary pollution during transport.

3. Relatively simple process, low investment cost, yields quick result once set up.

4. Making garbage management efficient, safe and recyclable, while creating an ecological industry model.

5. Product from degrading process can be reused, increasing value byproduct.

6. Low maintenance cost, stable performance, short fermentation period and wide range of application

7. Adaptive functioning, adjustable capability to different input material.

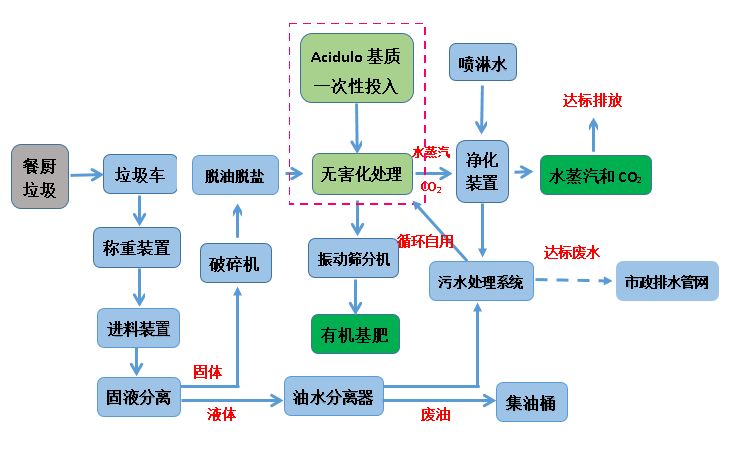

Kitchen Waste Treatment Process

Kitchen wastes are transferred to central treatment facility via collection tank, weighted and automatically unloaded into raw material collection pit, wastes go through preliminary solid/liquid separation and sorting, solid wastes are evenly sent into opposing roller shear machine via transporting equipment for crushing process, crushing of tough and large pieces in kitchen waste can help accelerate the microbial processing. Crushed wastes are then de-oiled and desalinized to maintain moisture content below 80%, after which they are sent into microbial processing machine for biodegradation, the de-oil and desalinization process ensures end product meets standards of organic fertilizer.Liquid separated in early process enters oil-water separator, separated into waste oil and waste water, waste oil enters oil collection barrel, while waste water is processed in water treatment equipment to national discharge standard, then discharged into municipal pipeline. Gas released during biodegradation goes through purification and dust suppression in air purifying device, ensuring any gas emitted into air meets national emission standards. Non-degradable inorganic matters are separated from weight-reduced product via vibration sieve, assuring final product contains no impurities, hence can be used for organic fertilizer.

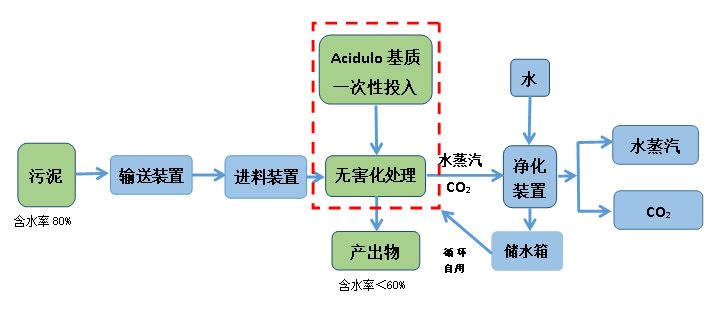

Sludge Treatment Process

Sludge with 80% moisture content enters feeding device via transfer device, then directly into bio-processing machine for biodegradation. Gas released during biodegradation goes through purification and dust suppression in air purifying device, ensuring any gas emitted into air meets national emission standards, such as GB14554 <Emission Standards for Odor Pollutants> and GB16297 <Comprehensive emission standard of air pollutants>. Also after 12-24 hours of high temperature and acidic bio-fermentation, sludge reduction reaches over 50%, accomplishing both weight reduction and hazardous component removal.